India's #1 Top Orthopedic Implants Manufacturer Company

These are called orthopedic implants, and the purpose is to replace or supplement a devastating skeleton part (bone or joint). Intervention by a surgeon is a remedy for fractures or severe deformations correction. Depending on the kind of injury and from which area injury issues severity, orthopedic implants can be made of metals, ceramics, or polymers. HCM-orthocare is one of the leading orthopedic implants manufacturers, suppliers, and exporters in India. All items are produced using advanced technology to offer efficient raw materials, so they have a long lifespan. You can find many implants on the market, for example, plates, screws, and nails used to fix bones and joints. Orthopedic is a term defined as a device that may have the capability of replacing or adding to that function of any damaged or diseased bone or joint. Currently, they are used for surgical procedures in fractures or inadequate body deformation correction. A diversity of metallic, ceramic, or polymeric orthopedic implant types is created, depending on the site and/or seriousness of the injury or condition. HCM Orthocare found itself one of the most excellent orthopedic implant manufacturing, supplying, and exporting companies of India. Most of the products are manufactured with newest technologies and very superior raw materials to ensure durable long-term performance of a variety of implants such as plates, screws and nails against several bone-joint injuries.

ORTHOPEDIC IMPLANTS MANUFACTURER

HCM Orthocare has been one of the leading orthopedic implants manufacturers and dedicated to bringing the best innovative ideas towards the surgeons and patients with the team of experienced and well-trained professionals who work painstakingly towards developing the new implant products to cater them into the present and ever-changing needs of the health-care . The state-of-the-art machines and quality standardizations inside our manufacturing set-up, production plants are indispensable contemporary constructs in manufacturing every innovation produced by us comparable to the best when talking about national standards or the global standards as well. Orthopedic implants are devices or artificial devices that preserve or restore the ability of an individual to function in the equipment or completeness of the musculoskeletal system to act during the time of injury, disease, or degeneration. They are put into operations to replace sick and damaged joints like the hip, knee, or shoulder and to set broken bones or repair abnormal features. Some of the metals used to make joint replacers include titanium, stainless steel or cobalt-chromium, since these are stronger and more durable, and safe to the body. Each of the implants differs in design, which fits where the implantation is taking place and the individualized needs of the patient. Add significant value to movement, relief of pain, and quality of life for persons with orthopedic complaints-such benefits cannot be overemphasized in human life.

ORTHOPEDIC IMPLANTS SUPPLIER

Orthopedic Implants Supplier HCM Orthocare is already proving very promising in establishing its footing as a renowned and trusted supplier for orthopedic implants since it becomes more global with all the growing networks of distributors who function much closer to knowing the needs of surgeons and patients to bring the best for these patients. It also carries pretty good range of products at most competitive and utilitarian prices.

ORTHOPEDIC IMPLANTS EXPORTER

HCM Orthocare operates as one of the major exporters of orthopedic implants to the international markets. We have developed strong partnerships with many distributors and healthcare organizations spread across the globe. Our products meant for broad-spectrum surgeries worldwide are all in compliance with the international regulations and standards. That assures that our products are safe and effective for the patients as well. Custom solutions related to orthopedic implants are offered to suit what each client requires in their markets.

WHAT DO ORTHOPEDIC IMPLANTS ENTAIL?

- Screws

- Plate

- Prostheses

TYPES OF ORTHOPEDIC IMPLANTS

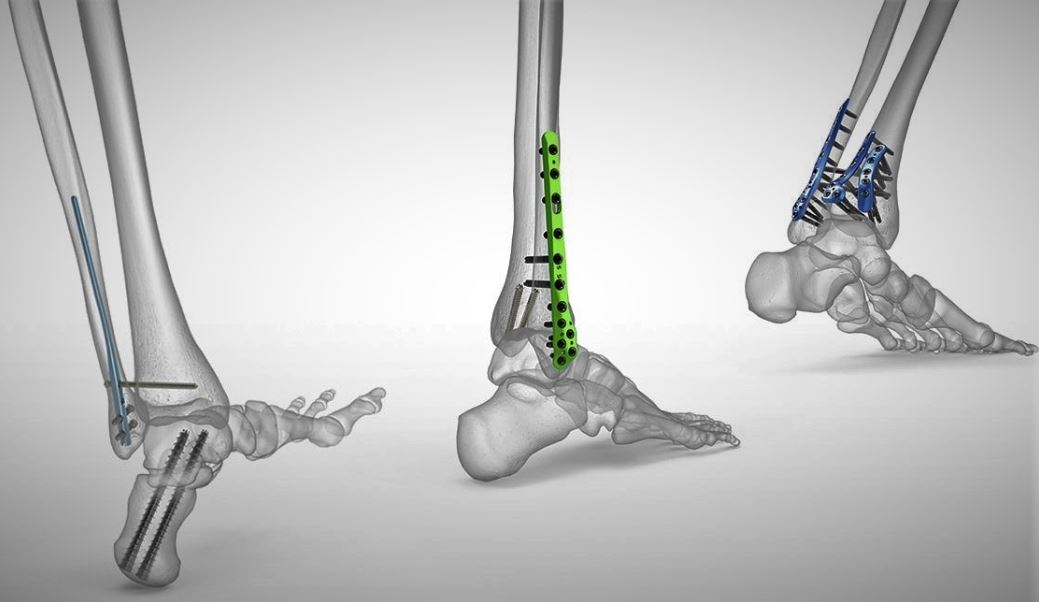

At HCM Orthocare, we take great satisfaction in being a top producer of superior orthopedic implants and instruments. Healthcare practitioners will always have access to the most dependable and efficient solutions for their patients because to our dedication to quality and innovation. In order to provide the best care and treatment possible, it is imperative to comprehend the many kinds of orthopaedic implants. Here, we list the main types of orthopaedic implants that HCM Orthocare offers.

Implants for joint replacement are intended to replace diseased or injured joints, thereby lowering pain and increasing mobility. The following are the most popular kinds of joint replacement implants:

- Hip implants: It is composed of various components such as femoral head, p.ace of where the joined or put together part is the acetabular cup and the stem of the femur.

- Knee Implants: Knee replacement requires the use of the femoral, tibial and patellar components of this kind of implants.

- Shoulder Implants: These are typically made up of glenoid component, the humeral stem and the humeral head and they are used in shoulder arthroplasty.

Trauma implants provide stability and help in the healing process when placed in treatment of fractures and other orthopaedic injuries. Of the kinds of trauma implant, it is important to have:

- Plates and Screws: The plates and the screws are meant to hold pieces of the broken bone fragments so they would not fat, plates and screws are produced in a variety of sizes and shapes to enable them to suit different fractures.

- Intramedullary Nails: These are metal rods of long length inserted into a medullary cavity of bone to stabilise the fractures particularly in large bones such as those of the femur and tibia.

- External fixators: External fixators are the tools applied outside the body to fix bone alignment at a right angle during healing.

Spinal disorders include degenerative disc degeneration, scoliosis, and spinal fractures are treated using spinal implants. Important spinal implants consist of:

- Pedicle screws: These screws are used to stabilise the vertebrae during spinal fusion surgeries.

- Interbody Cages: These are the implants being inserted into the gaps between the vertebra to keep the disc height and to promote bone fusion.

- Rods and Plates: Rods and plates with screws provide extra stability of the spine and straightening.

- Bone Grafts: The grafts are Allografts, donor tissue, or autografts, which are taken out of a patient to stimulate bone growth and the healing process.

- Bone Substitutes: Artificial materials that are created to look like the real bone and accelerate the healing process.

- Growth Factors: These are proteins that enhance cell division and growth, which enhance the ability of the body to repair damaged tissue.

- 3D-Printed Implants: These Implants are designed based on precise imaging information through the application of the latest technology of 3D printing, which ensures an optimal fit and performance.

- Custom Plates and Screws: By correctly fitting implants to the anatomy of the patient, customisation lowers risk and speeds up healing.